When a friend from UNBC first mentioned Spark Lab to me, a start-up 3D printing/maker space in the Wood Innovation and Design Building in downtown Prince George, I knew I had to see it for myself. As someone who’s been into 3D printing and 3D modeling for a while now, I was super excited to find a space where I could work on my projects. I’ve owned my own budget 3D printer for 2 years now and I was excited to have a place to put it other than in the closet of my tiny dorm room (it’s very loud and very sketchy).

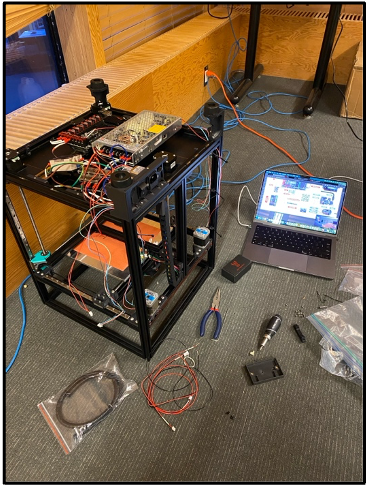

One of the coolest things about having access to Spark Lab is the ability to use their high-end fully enclosed 3D printer. This has been a game-changer for me, as I’ve been dreaming of building my own printer using 3D printed parts. The printer I chose to build is a Voron, an open-source project made by a group of engineers. The printed parts need to handle high temperatures and long-term strain, which means you need to print with acrylonitrile butadiene styrene (ABS) or acrylonitrile styrene acrylate (ASA). This requires an enclosed printing chamber to minimize warping and carbon filtration to handle the toxic fumes that come with printing these types of plastics. Also, it needs a lot of space and tools to build, as it can get a little messy (see the picture of me working on the electronics). Without the lab, this project would have been way more challenging and expensive to pull off.

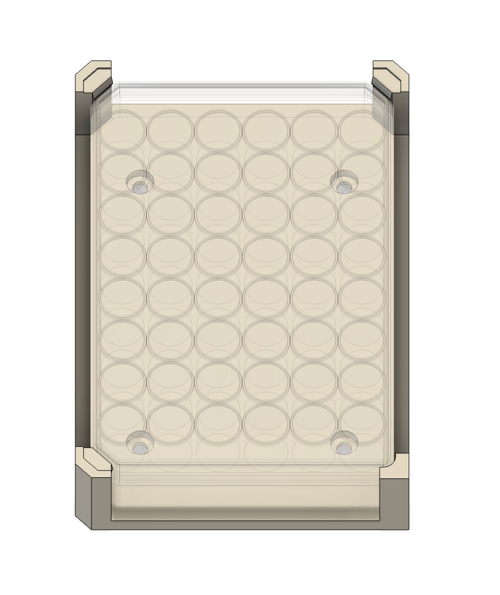

Being involved with Spark Lab means I have had the chance to work on projects that directly impact the community. I’ve had the opportunity to design and print tools for researchers, which has not only helped me level up my skills in 3D design but has also allowed me to gain experience working with clients in a relaxed environment. One project that really sticks out in my mind involved designing and printing a culture plate holder that could be screwed into an orbital shaker, providing a much safer and robust solution than the researcher’s previous method of using tape. The picture on the left is the 3D model in Fusion 360.

Another thing I love about Spark Lab is being able to contribute to the space’s growth and development. It’s been great to come up with ideas for new equipment, figuring out the layout, and having the freedom to rearrange and organize the space in a way that works for everyone. Right now, the lab only has a few 3D printers and basic electronic tools, but we’re working on getting our hands on a laser cutter, a desktop 3-axis CNC machine, more power tools, and even some bean bag chairs for just hanging out.

To be honest, I was a bit unsure about the lab’s downtown location at first, thinking it might be a pain to get there. But I was pleasantly surprised to find that the commute was easier than I thought (even on a bike) and having an ongoing project at the lab gave me the extra push I needed to make the trip regularly. It’s also nice to get off campus and see other parts of Prince George. As a start-up space, Spark Lab is still growing and evolving (the name might change in the future), and that’s what makes it so exciting to be a part of. I can’t wait to see where this journey takes us and how the lab will continue to support the maker community in Prince George. If you’re a creative type looking for a place to bring your ideas to life, give Spark Lab a shot – you might just find your new favorite hangout spot!